-

Home

- About

糖心LOGO官方网站在线观看免费| 国产精品9999久久久久| 91久久综合九色综合欧美98| 无码毛片一区二区本码视频| 国产亚洲欧美精品手机在线| 丝袜美腿一区二区三区| gogogo高清免费观看直播的| 成人无码区免费aⅴ片| 老熟女高潮一区二区三区| 国产亚洲视频在线观看|- Products

- News

- Agents

- Recruitment

Product CenterClassify

Product CenterClassify- CNC Lathe

- High Precision Automatic Lathe

- CNC Centring Machine

- Fully Automatic Feeder

Fully Automatic Feeder

- Product Description

1. Suitable for matching small CNC lathe processing, convenient and practical.

2. Optional shock-proof, electronic synchronization device is suitable for efficient machining of cutting machine.

3. Using motor control, divided into three sections to open the warehouse, for small materials, effectively avoid material rush and skein.

4. Using pulse data control, accurate positioning, the cutting end of the first piece can be controlled within 0.2mm.

5. Adopt 40 PLC plus servo motor, large touch screen, digital control, accurate positioning, convenient and simple.

6. The silo is made of high-temperature, wear-resistant and oil-resistant PU material, which makes no noise in material transmission and avoids scratches.

7. Electrical and mechanical fault intelligent diagnosis, maintenance is simple and fast.

8. Material out or cutter damage, intelligent alarm and automatic shutdown, to ensure safety, and reduce energy and tool loss.

9. For different products, you can choose one opening clip and two opening clips, which can accurately control the refuelling in the same position.

10. According to customer order requirements, the processing quantity can be set to facilitate production management.Item

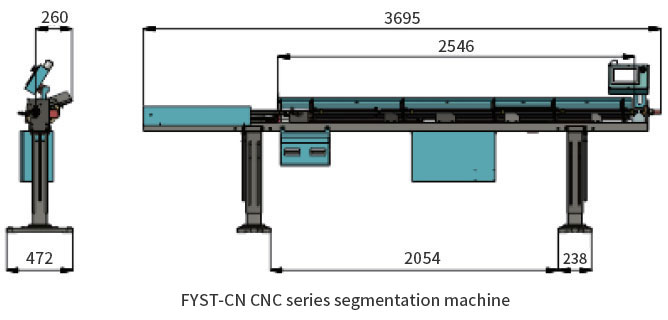

FYST-CN-08

FYST-CN-10

Processing capacity range

Maximum diameter of material processed

φ8mm

φ10mm

Minimum diameter of material processing

φ1.4mm

φ2mm

Bar processing length

2550mm

Bunker activity range

φ9mm

φ11mm

synthesis

Material capacity

φ1.4mm*140pcs

φ8mm*25pcs

φ2mm*100pcs

φ10mm*20pcs

Maximum power

0.465KW

Maximum frequency

50HZ

Total machine weight

About 180KG

Overall dimension

-

About Us

Company Profile Chairmans Speech Culture Honor Patent Enterprise Style Partner -

Products

CNC Lathe High Precision Automatic Lathe CNC Centring Machine Fully Automatic Feeder -

News

Enterprise Dynamics Industry News Common Problem -

Contact Us

Hotline: 4008-166-588 Phone: +86 138 2577 2521 Mr. Xiao Tel: +86 769-81587551 E-mail: 1045100229@qq.com Add: No.4, Lane 1, Yongkou Hebin Road, Houjie Town,

Dongguan City, Guangdong Province, China Service NetworkMessage

Copyright ©2024 Dongguan Taiyang Precision Machinery Co.,Ltd.Technical support: Tianzhuyun - About